Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

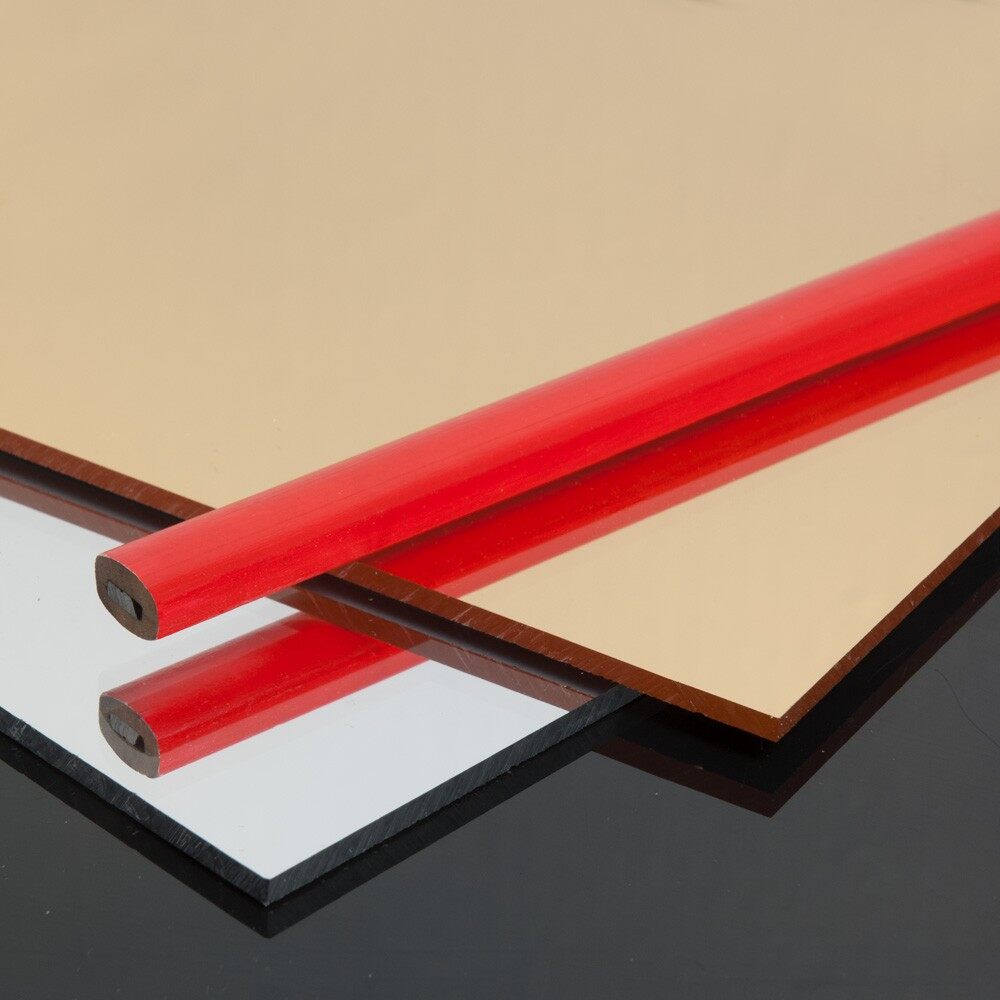

CNC Cutting Acrylic Sheet

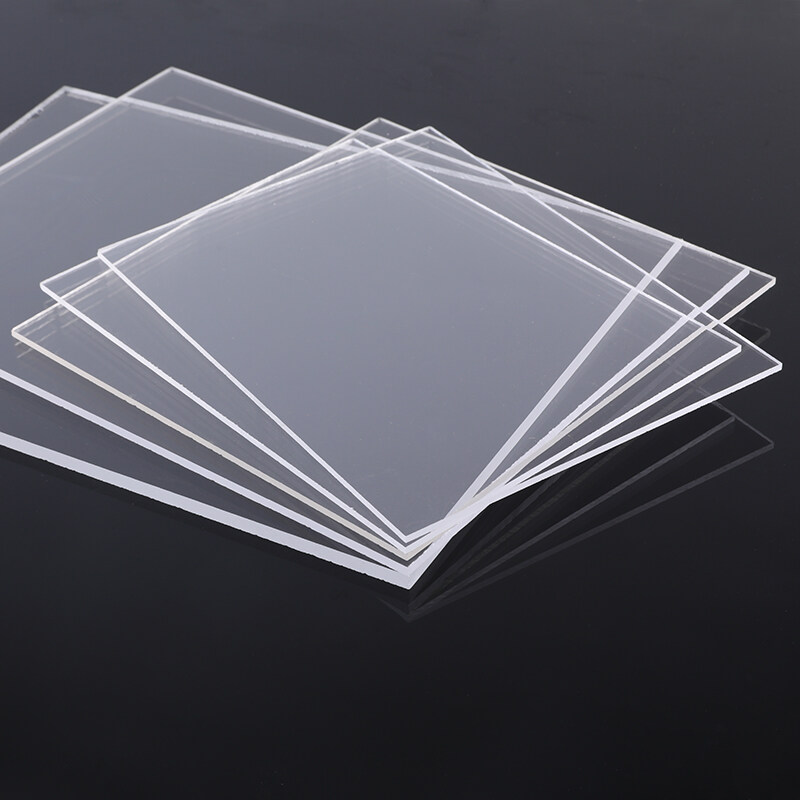

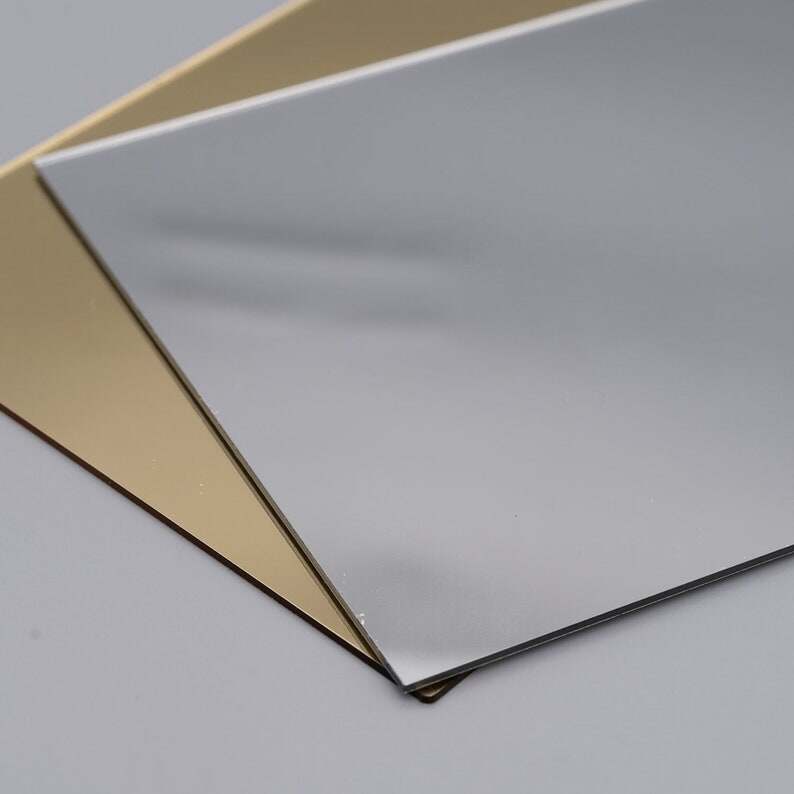

Our high-quality CNC Cutting Acrylic Sheet, perfect for precision cutting and shaping. This acrylic sheet is specifically designed for CNC cutting, ensuring accurate and clean results every time. With its durable construction, it can effortlessly handle various applications, including plexiglass and plastic sheet cutting. Experience the convenience and efficiency of CNC technology with our reliable acrylic sheet.

Description of CNC Cutting Acrylic Sheet

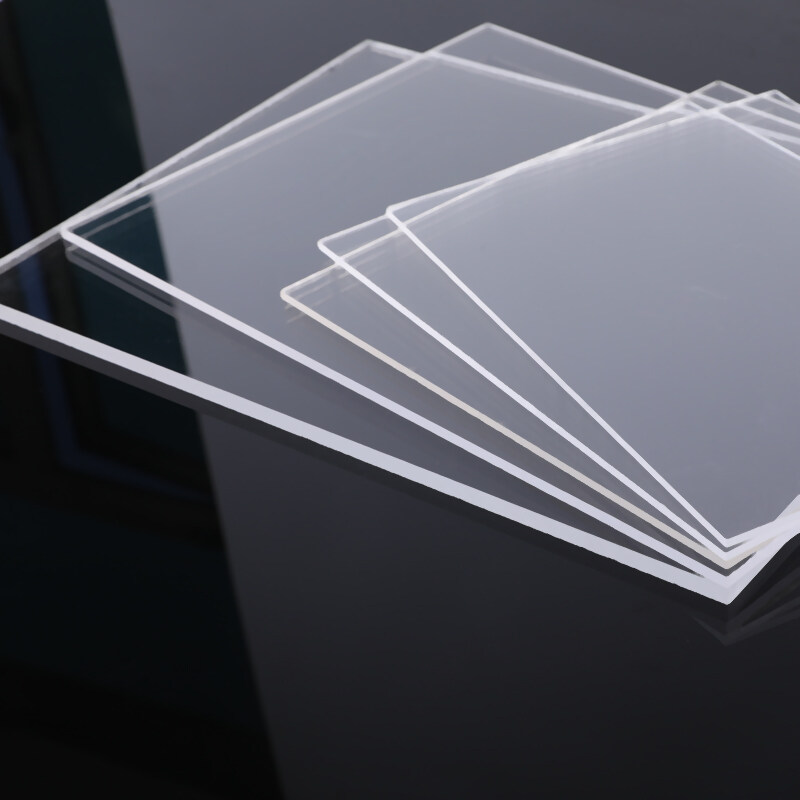

The CNC Cutting Acrylic Sheet is a premium material tailored for precision and durability. Utilizing advanced CNC plexiglass cutting technology, these sheets are crafted to exact specifications, ensuring a perfect fit for intricate designs and applications. Known for its clarity and strength, the CNC cutting acrylic sheet is an ideal choice for projects requiring meticulous detail and high-quality finish.

Features of CNC Cutting Acrylic Sheet

- Precision Cutting: CNC acrylic sheet cutting delivers components with exact shapes and sizes, enhancing the fit and function of the final product.

- Reduced Waste: The precision of cutting acrylic sheet CNC ensures minimal material waste, contributing to cost-effectiveness and sustainability.

- Impact Resistance: Acrylic sheet CNC cutting boasts a high level of impact resistance, making them suitable for demanding environments.

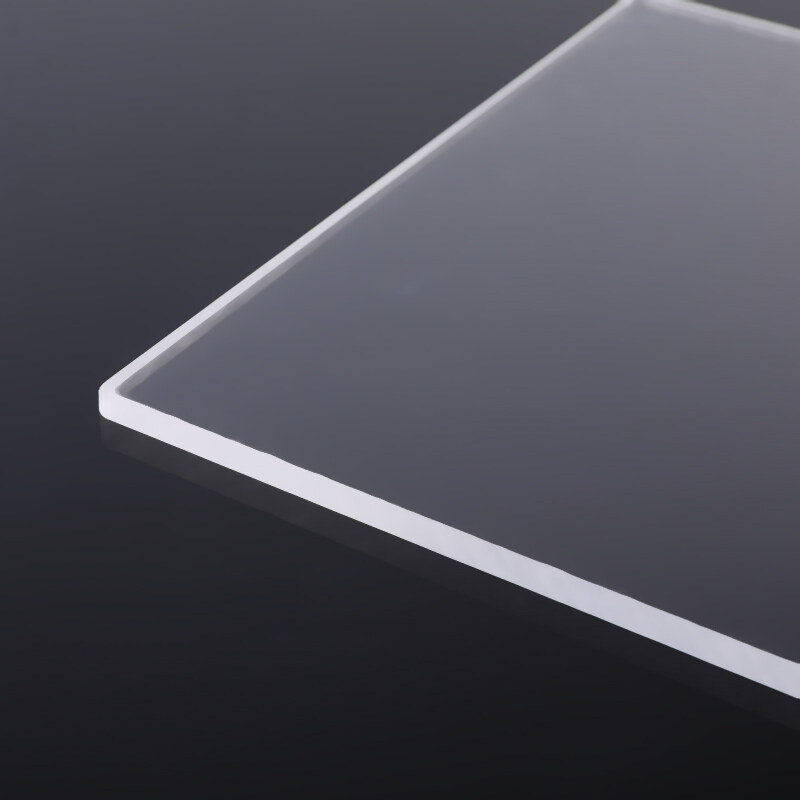

- Optical Clarity: The transparency of the cutting acrylic sheet CNC material is perfect for applications requiring clear visibility.

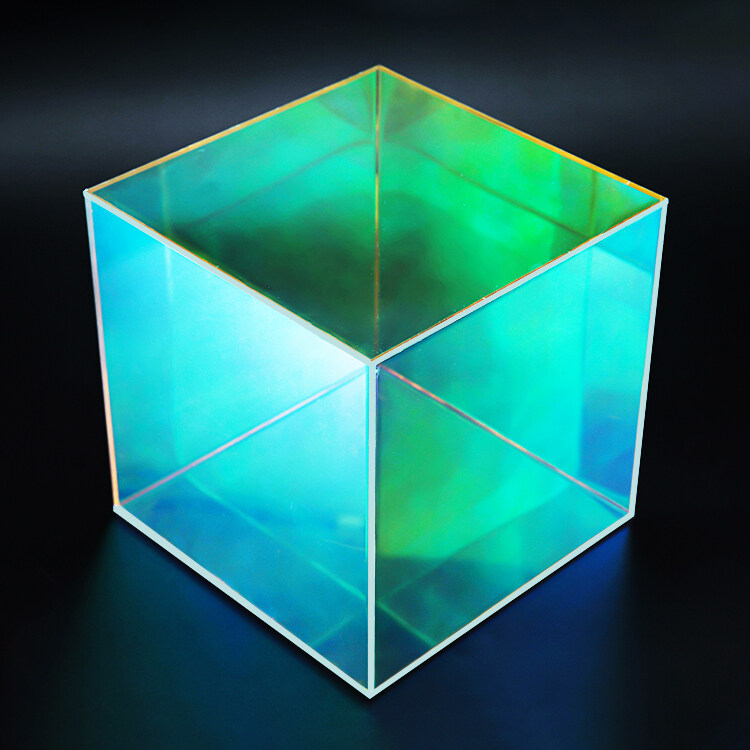

- Versatility: CNC cutting plastic sheet technology allows for a wide range of applications, from simple to complex geometries.

- Dimensional Tolerance: Improved dimensional tolerances are achieved, ensuring components meet strict industry standards.

Applications of CNC Cutting Acrylic Sheet

- Optical Components: CNC cutting acrylic sheet is optimal for fabricating exacting parts such as lenses for glasses and contact lenses, ensuring precision and comfort.

- Building Features: These sheets are frequently selected for constructing durable and clear architectural elements, including windows, doors, and enclosures for greenhouses.

- Illumination Solutions: The material’s inherent clarity makes it an excellent choice for designing lighting fixtures and diffusers that evenly distribute light.

- Healthcare Equipment: In the medical field, CNC acrylic sheet cutting is instrumental in manufacturing sterile and precise items like cuvettes, connectors for medical tubing, and organized surgical trays.

- Technology Displays: The robustness and optical clarity of CNC cut acrylic sheets make them ideal for use in electronic displays and as protective barriers for various devices.

FAQ

Q: Can CNC machines cut intricate designs on acrylic sheets?

A: Yes, CNC machines are capable of cutting highly detailed and complex designs on acrylic sheets with precision.

Q: Is the CNC cutting process suitable for large-scale production?

A: Absolutely, CNC cutting is efficient and can be scaled up for high-volume production while maintaining accuracy and consistency.

Q: How do you maintain the quality of the CNC cutting acrylic sheet during the cutting process?

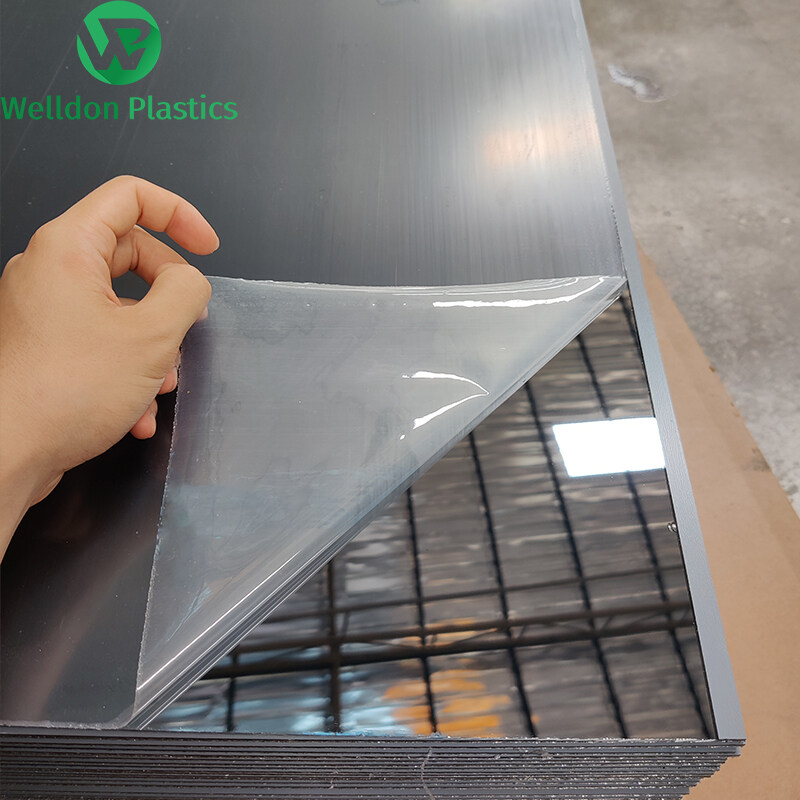

A: The CNC machine applies the right amount of force to prevent damage, and the sheets are often protected with a film to maintain surface quality during the process.