Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Other Functional Acrylic Sheets

Other Functional Acrylic Sheets

(16)Functional Acrylic Sheets are the perfect solution for your home and office needs. Our clear hard coated acrylic sheets are designed to be durable, scratch-resistant, and easy to clean. The acrylic sheets are made of a high-quality, lightweight material that is both shatter-resistant and UV-resistant, making them ideal for both indoor and outdoor use.

The acrylic sheets are perfect for creating a modern, contemporary look in any room. They can be used to create a sleek, clean look for a kitchen countertop, a coffee table, or a desk. The sheets are also perfect for use in workshops or garages, where they can be used to create a protective barrier between tools and other items.

Our Functional Acrylic Sheets are easy to install and come in a variety of sizes and thicknesses. The sheets can be cut to fit any space and can be used to create a unique look for any room. The sheets are also easy to clean and maintain, making them a great choice for any home or office.

Xishun's functional acrylic sheets are designed to provide maximum durability and protection against wear and tear. The sheets are made to last and are perfect for any home or office. They are also perfect for creating a modern, contemporary look in any room. With our clear hard coated acrylic sheets, you can create a unique look that is both stylish and functional.

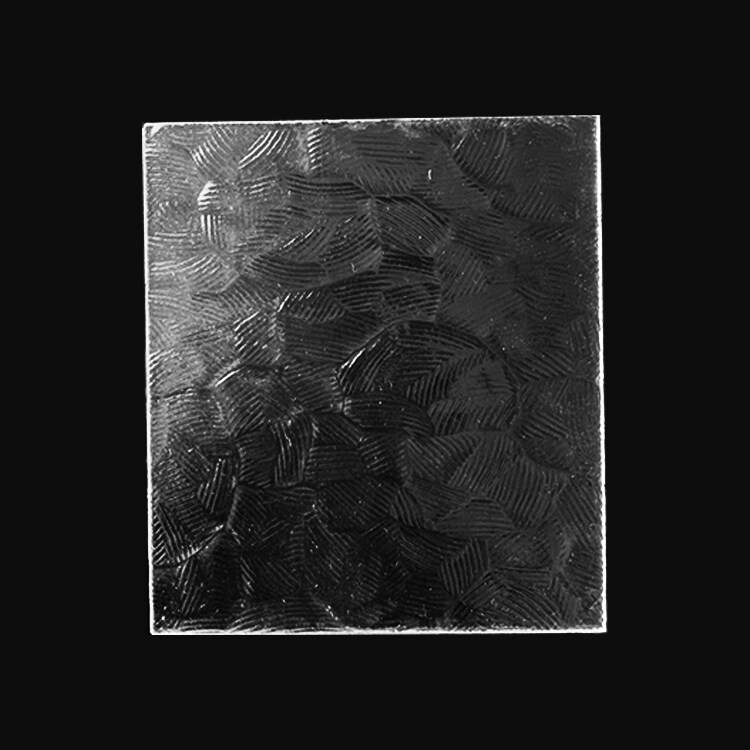

Big Flower Patterned Plexiglass Sheets/Panels

Our big flower patterned plexiglass sheets/panels are the epitome of style and sophistication. Designed to captivate and inspire, these panels are perfect for creating statement pieces in any setting. From room dividers to feature walls, the intricate flower patterns etched into the plexiglass provide a visually appealing and contemporary look.

Chunky Glitter Acrylic Sheet

Dazzle your projects with the sparkling elegance of our chunky glitter acrylic sheets. These sheets are infused with shimmering particles that catch the light and create a stunning, eye-catching effect. Perfect for a variety of applications, from retail displays to decorative elements, our glitter acrylic sheets add a touch of glamour to any setting.

Marble Pattern Effect Acrylic Sheet

Marble acrylic sheets combine the timeless elegance of marble with the practical advantages of acrylic. These sheets are not only durable and lightweight but also offer a sophisticated marble appearance that enhances any design project. Ideal for use in interior design, architectural accents, and modern furniture, they provide a cost-effective solution for achieving a high-end look.

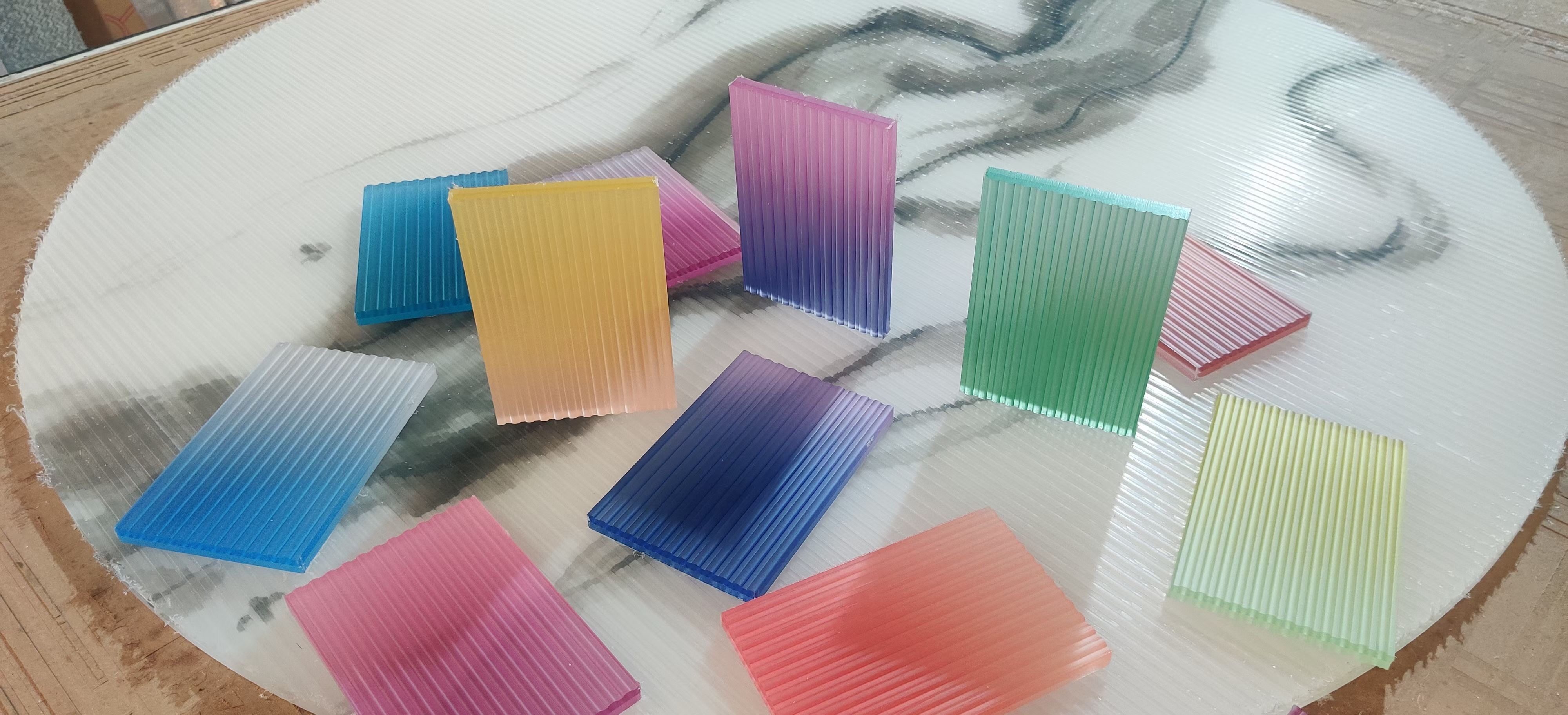

Colored Patterned Acrylic Sheets

The colored pattern acrylic sheet is designed for exceptional adaptability and resilience, capable of withstanding the rigors of the external environment. Its robust composition ensures that its performance remains unaffected even after prolonged exposure to harsh weather conditions, including wind, rain, and the relentless sun. With built-in anti-aging properties, this acrylic sheet is a reliable material for outdoor applications, offering both longevity and safety.

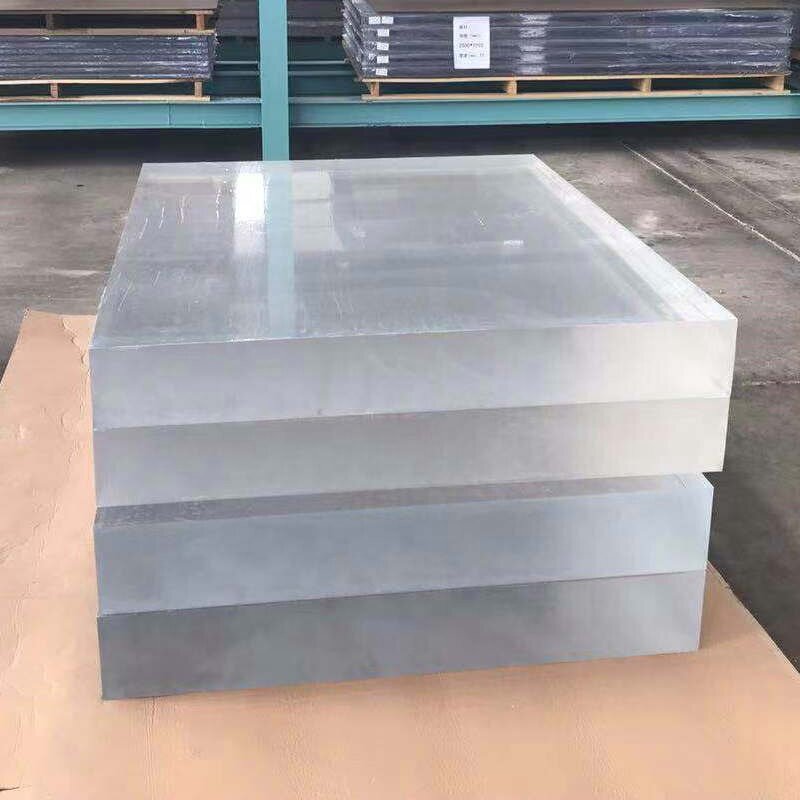

Aquarium Acrylic Sheet

The aquarium acrylic sheets are ideal for the large aquariums due to their strength and lightness, making them easy to move. While prone to scratches, careful cleaning can manage this issue. Acrylic tanks have durable, well-bonded seams and offer the versatility to create unique shapes. They also allow for easier drilling for fittings, enhancing customization options.

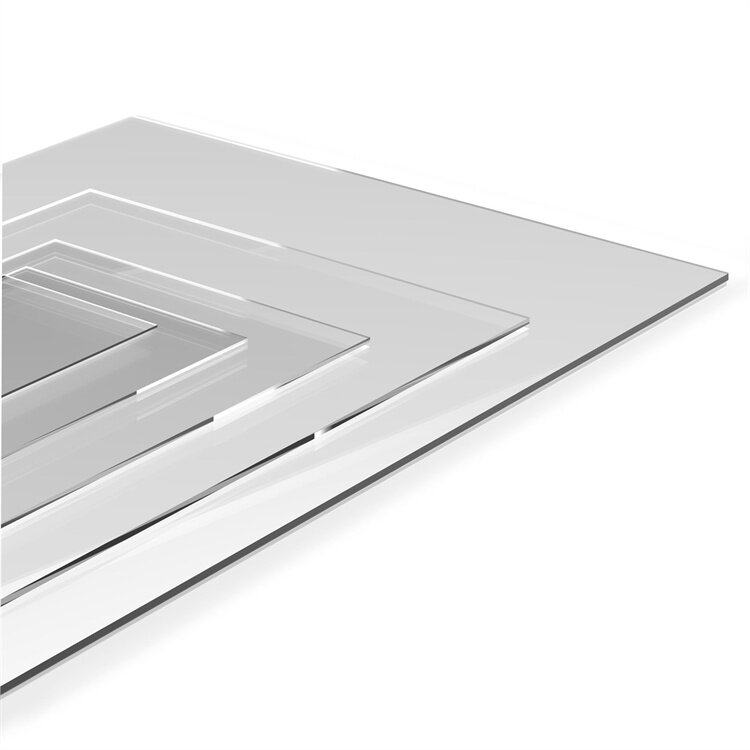

Clear Acrylic Perspex Sheet Custom Cut to Size

Introducing our Clear Acrylic Perspex Sheet Custom Cut to Size! This versatile product offers endless possibilities for your projects. With our custom clear acrylic sheets, you can achieve the perfect fit for any application. Whether you need a custom size clear acrylic sheet, custom perspex sheet, or custom plexiglass, we've got you covered. Experience the clarity and durability of our clear acrylic perspex sheet, precisely cut to your desired dimensions.

Diffuser Acrylic Sheet

A combination of components is used in acrylic that diffuses light to allow light sources pass through plastic. These acrylic sheets' light diffusion improves the clarity of the image for the viewer whether you use LED lights or fluorescent bulbs.

Lgp Acrylic Sheet

A transparent acrylic panel manufactured from virgin sheets of pure PMMA is called a Light Guide Plate (LGP) acrylic sheet. It uniformly disperses the light from the light source across the acrylic panel's entire top face. It is essential for maximizing light uniformity, creating a compact backlight, and reorienting lines or dot light sources, like LEDs or accent lamps, to the plate light source.

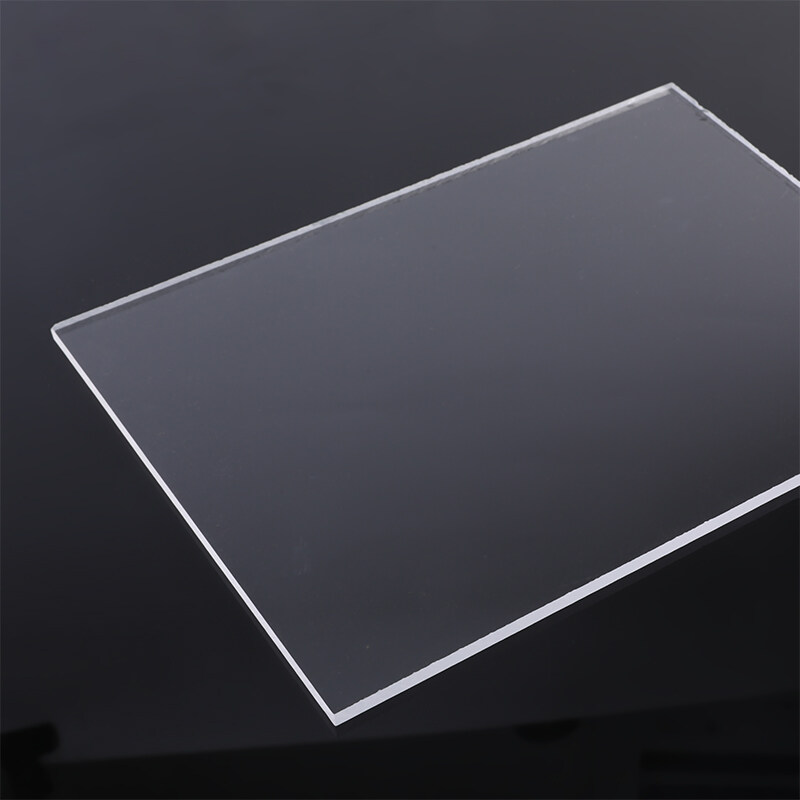

Hard Coated Acrylic Sheet

Discover the ultimate solution for durability and clarity with our hard coated acrylic sheets. Engineered to withstand the rigors of demanding environments, these sheets provide a robust surface without sacrificing the lightweight and versatile nature of acrylic. Ideal for a broad range of applications, our hard coated acrylic sheets are the top choice for professionals seeking longevity and performance.

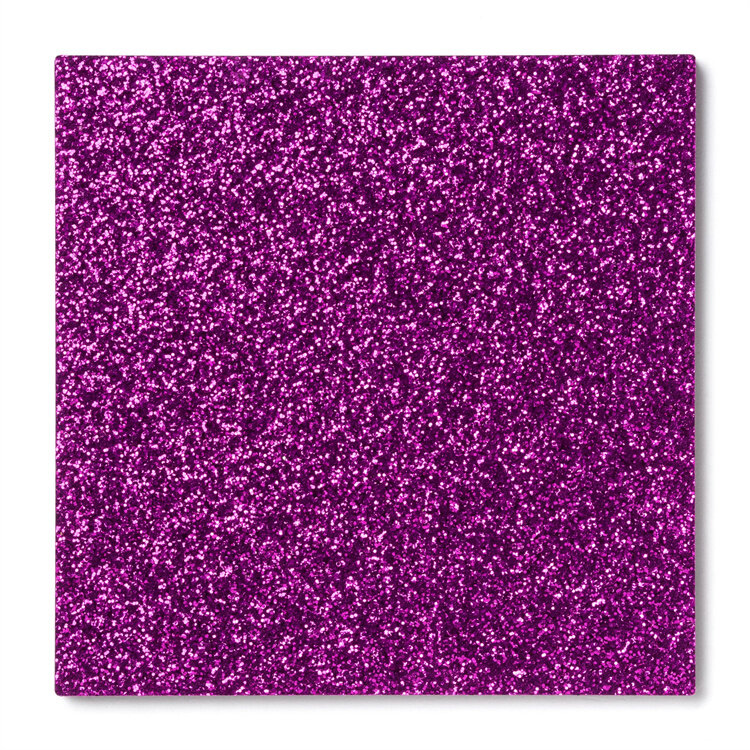

Glitter Acrylic Sheet

The only real distinction between the premium glitter sheet and other ordinary cast acrylic sheets is where the shimmering glitter particles are embedded. The distinctiveness of the wide variety of colours and patterns makes them perfect for use as point-of-purchase displays, store fixtures, novelty items, accessories, lighting and signs or lettering. Due to the glitter flakes, laser cutting requires a little bit more power.

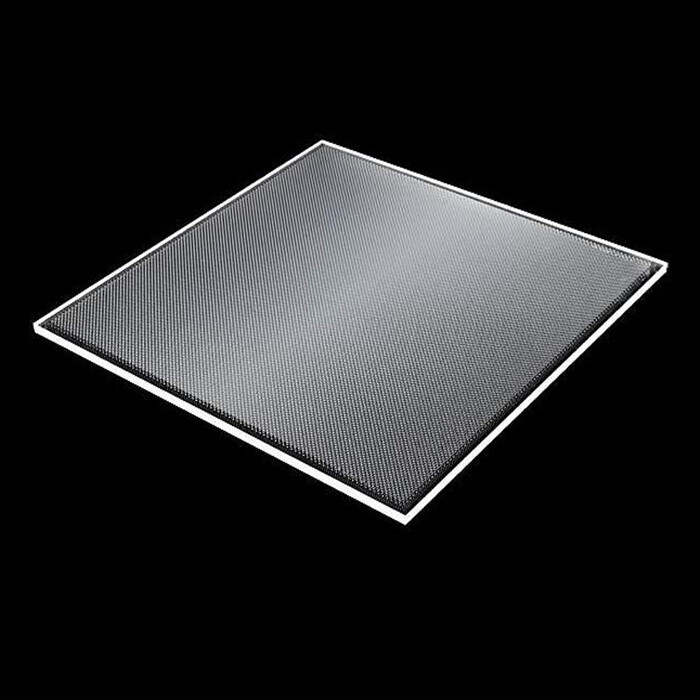

Anti-Glare Acrylic Sheet

A sheet of clear extruded acrylic that has been given a matte coating on one side to lessen glare and reflection. Useful in situations where strong illumination may result in distracting reflections. High-quality acrylic sheet with a high level of light transmission is anti-glare acrylic sheet. Extruded acrylic has a marginally lesser quality than cast acrylic, but because of its more cost-effective manufacturing process, it is a less expensive material to buy.

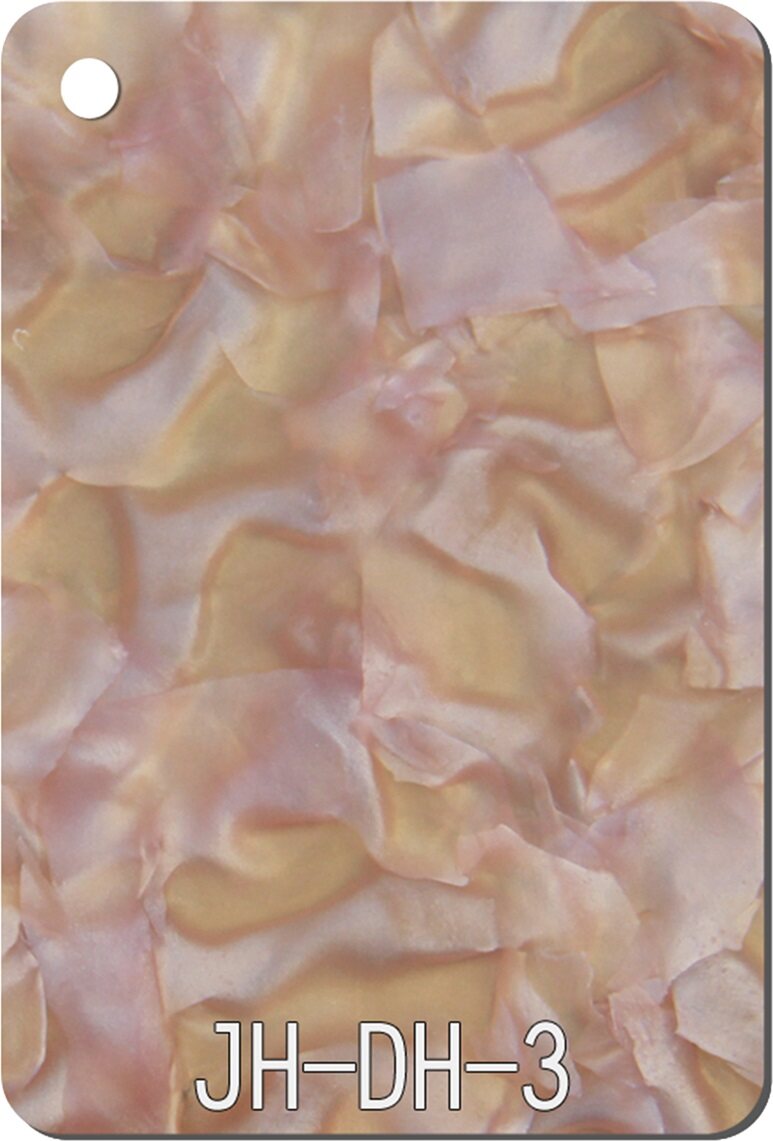

Colored Pearl Shell Acrylic Sheet/Pearlescent Shell Acrylic Sheet

With a subtly shimmering shine, pearlescent shell acrylic sheets are utilised to produce amazing effects. For designers looking for sophistication and premium appeal for their applications, it provides a hint of grace. Retail displays, point-of-sale displays, visual communications, furniture, and interior designs frequently employ pearlescent shell acrylic sheet.