Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

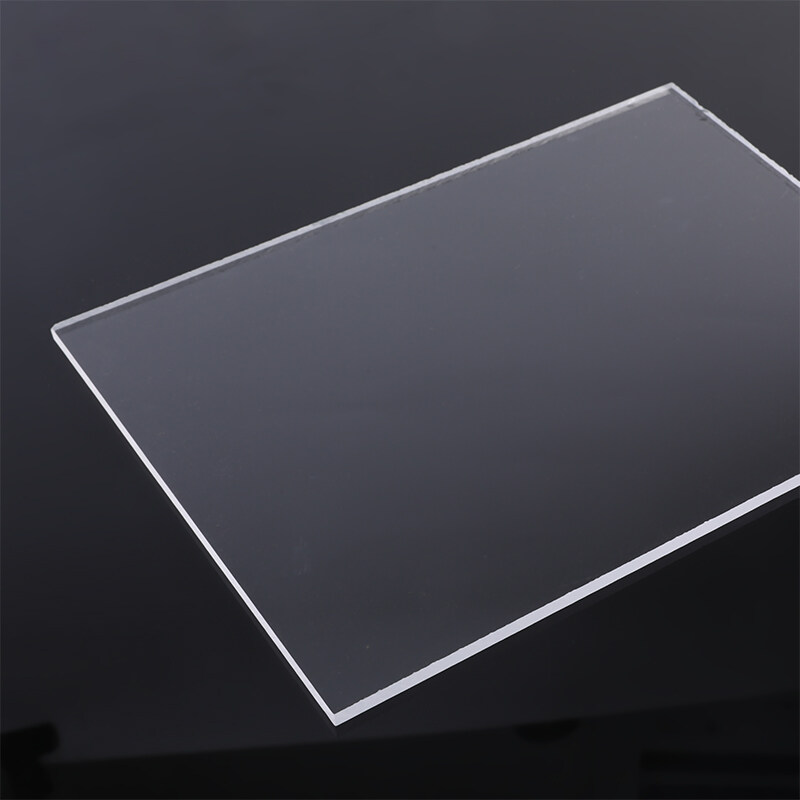

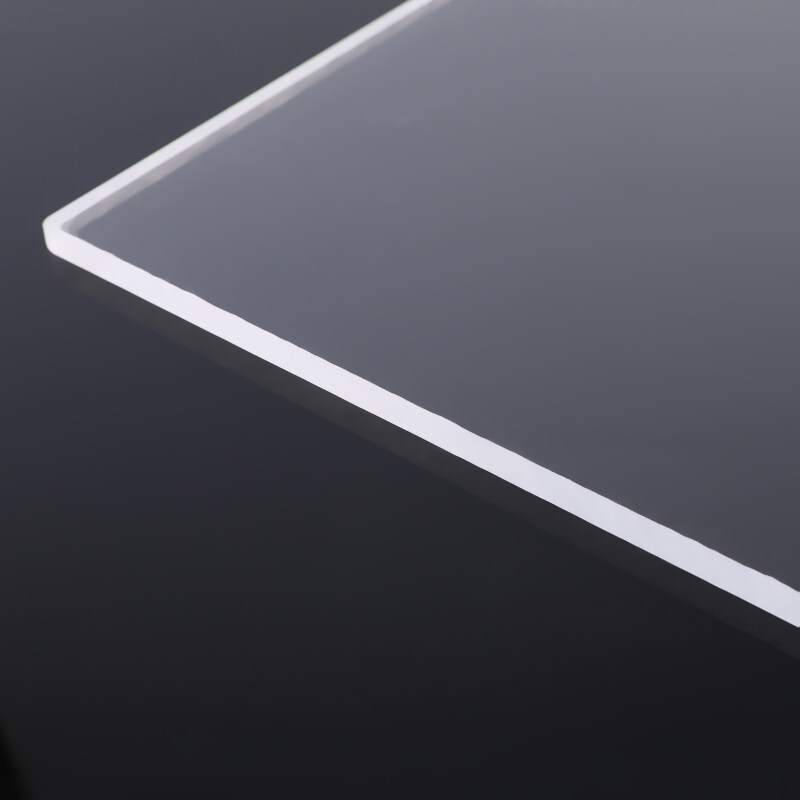

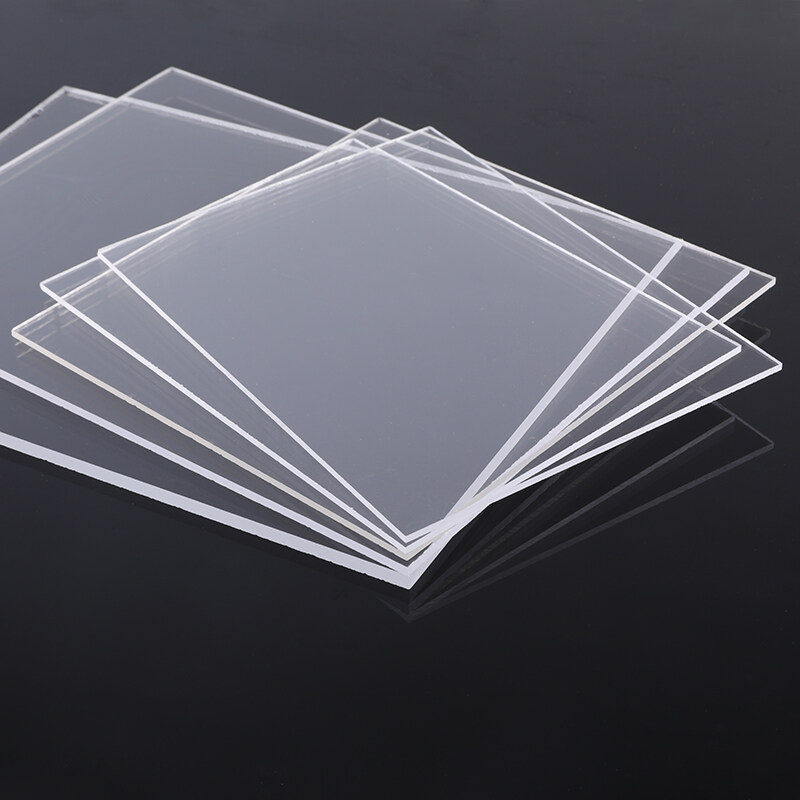

Anti-Glare Acrylic Sheet

A sheet of clear extruded acrylic that has been given a matte coating on one side to lessen glare and reflection. Useful in situations where strong illumination may result in distracting reflections. High-quality acrylic sheet with a high level of light transmission is anti-glare acrylic sheet. Extruded acrylic has a marginally lesser quality than cast acrylic, but because of its more cost-effective manufacturing process, it is a less expensive material to buy.

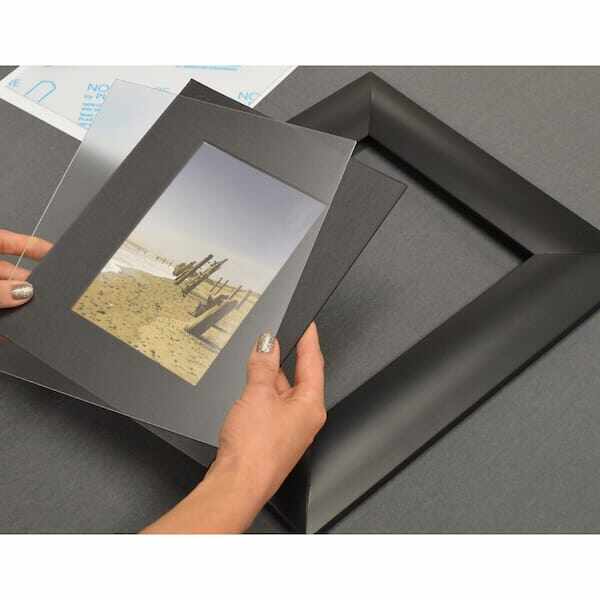

The anti-glare acrylic sheet has a matte finish, designed to minimize glare and reflection from most viewing angles. It is commonly used in art galleries and museums to display artwork, prints and photographs.

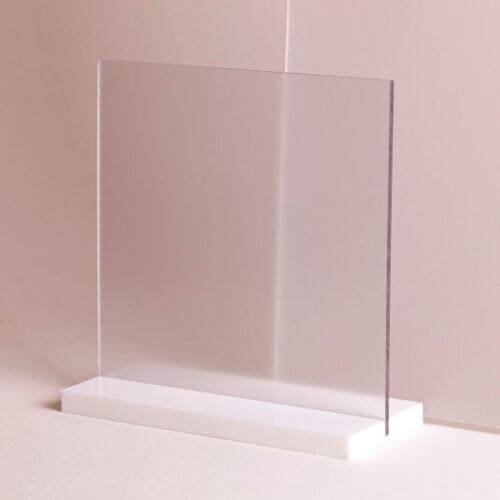

Suitable for use for applications where high lighting levels can cause distracting reflections. Ideal for use in galleries, exhibitions, shops and the home where the strong lighting can often cause irritating glare which detracts from the viewing experience.

A clear extruded acrylic sheet with a slightly matte surface finish on one side to reduce glare and reflection. Suitable for use for applications where high lighting levels can cause distracting reflections.

Anti-glare acrylic sheet is a high-quality acrylic sheet material with a high level of light transmission. Extruded acrylic is of a slightly lower quality than cast acrylic but its production process is more economical making it a lower-cost material to purchase.

Specifications

| Product Name | Anti-glare Acrylic Sheet |

| From | China anti-glare acrylic sheet factory - Xishun |

| Origin | Foshan, China |

| Material | PMMA Acrylic |

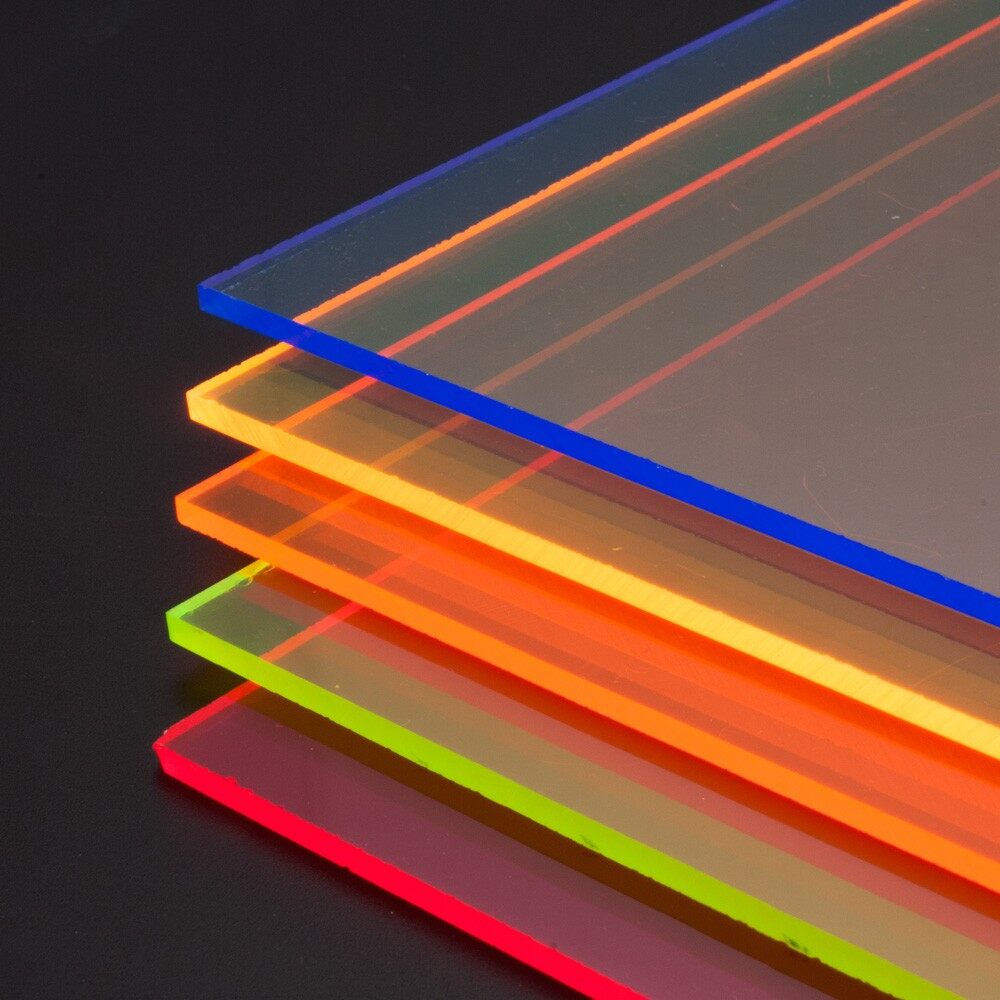

| Color | Clear/transparent |

| Types | Acrylic sheets |

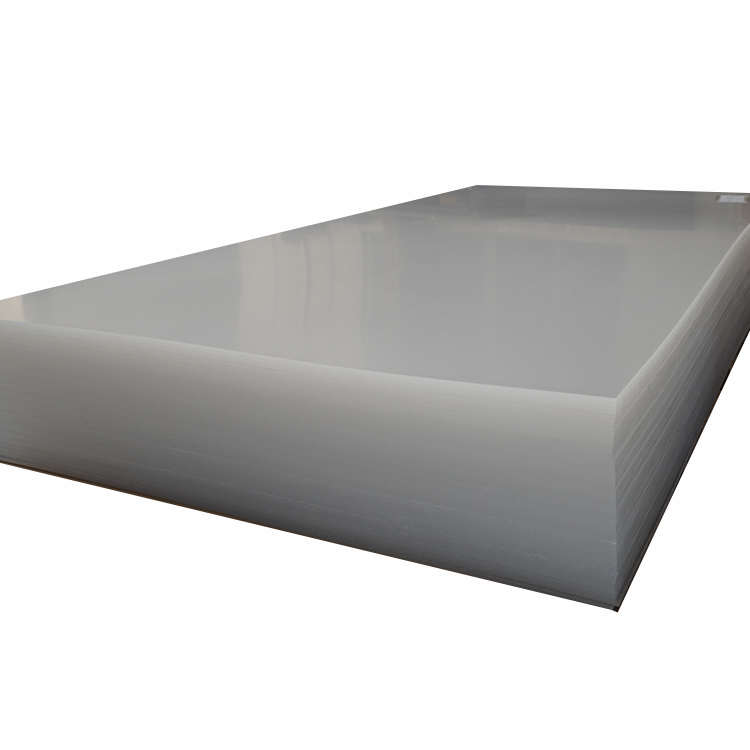

| Size | 1220*2440mm or customized sizes. |

| Thickness | commonly 1~20mm. |

| Density | 0.4~1.05g/cm |

| Processing Services | Moulding, Cutting, Polishing, Drilling, UV Printing, etc. |

| Supply Ability | Around 700 tons/month |

| Applications of anti-glare acrylic sheet | Art galleries, museums,artwork, awards&wall plaques, forming & fabrication,retail displays, point of sale displays, construction, home decor, POP, signage, models and display cases, glazing, photo framing, picture framing, poster framing, framed projects, etc. |

Key features

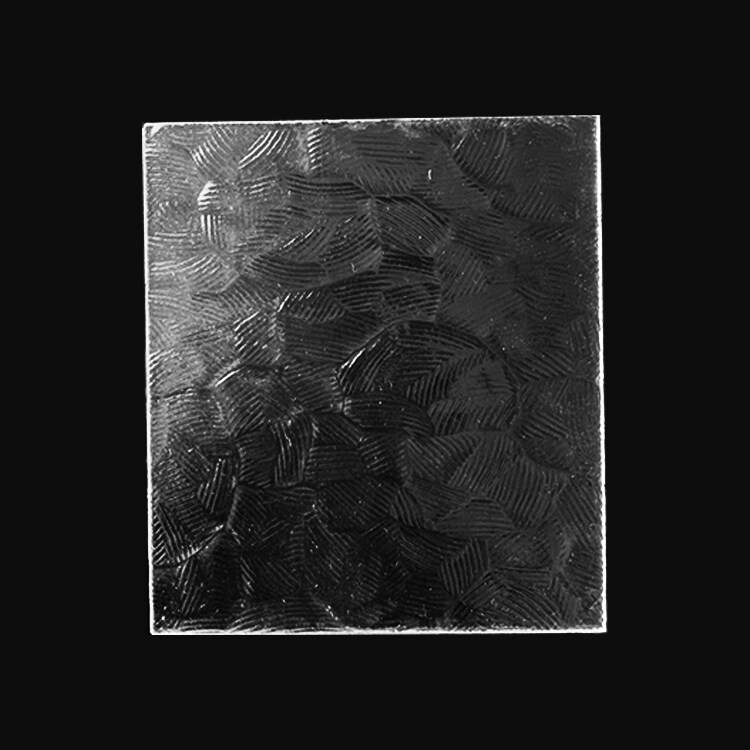

- Anti-glare surface

- Excellent thickness tolerance

- Optical clarity

- Hard wearing

- Weather resistant

- Easy to bend and shape

- Economical

- Suitable for vacuum forming

- Resistance against figure marks

Typical applications

Point of sale

Retail display

Glazing

Picture framing

Advantages of Anti-glare Acrylic Sheet

1. anti-glare surface.

2. excellent thickness tolerance.

3. optical clarity.

4. hard wearing.

5. weather resistant.

6. easy to bend and shape.

7. economical.

8. suitable for vacuum forming.

9. resistance against figure marks.

Detailed infomation

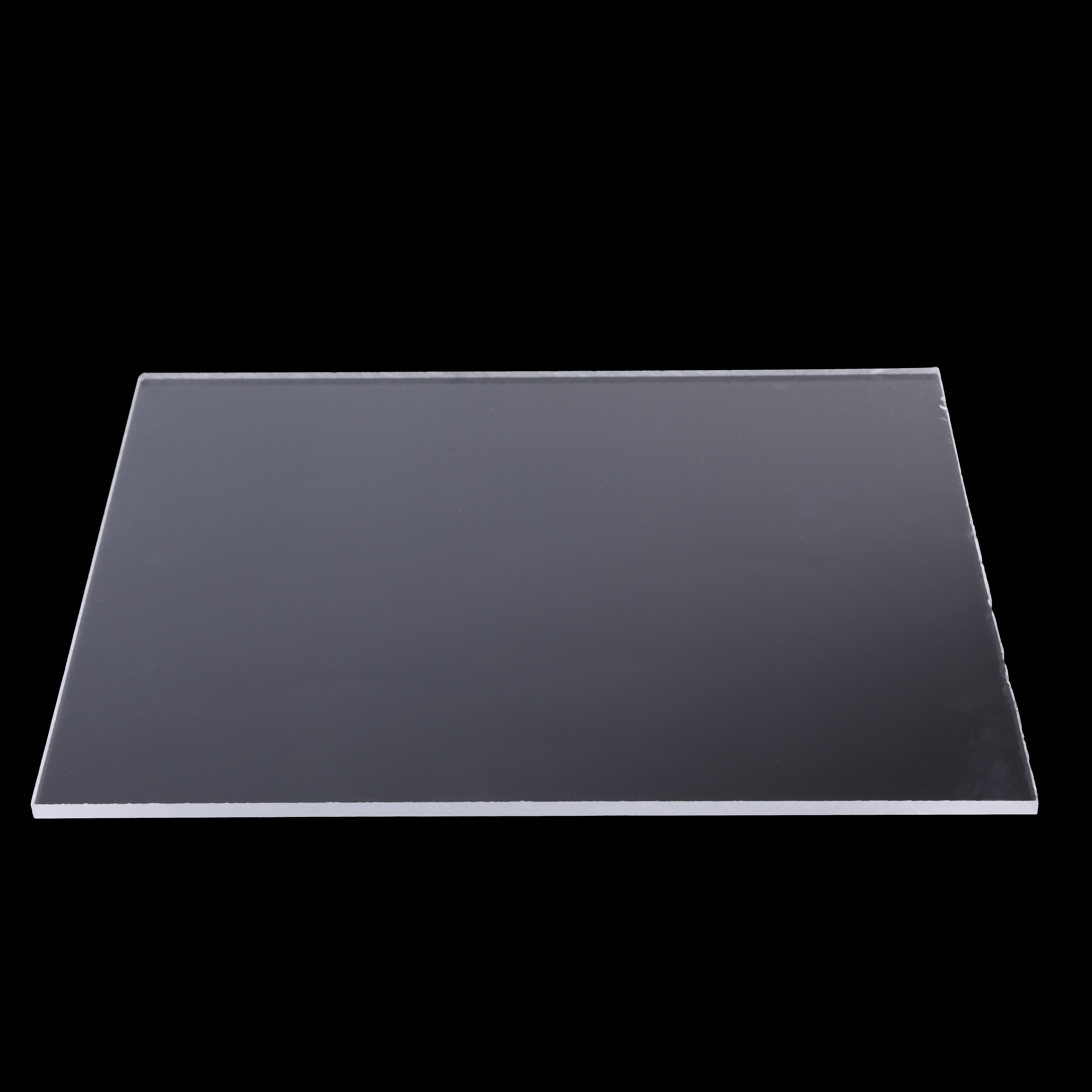

- Anti-Glare

Produced with a fine matte surface on one side to help avoid glare by reducing reflection.

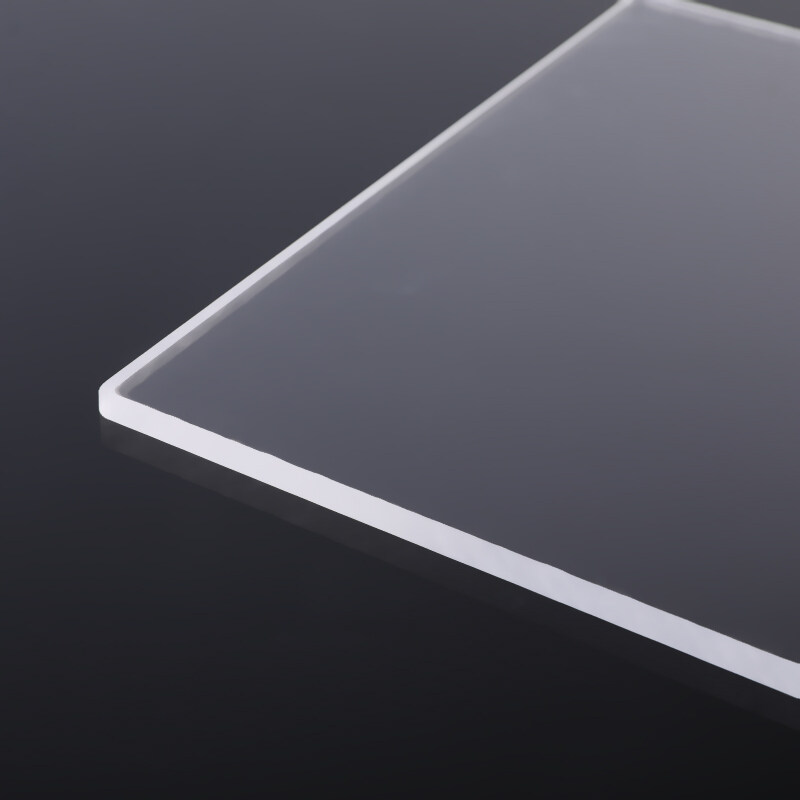

- Excellent thickness tolerance

Extruded acrylic has an excellent thickness tolerance meaning there is little variation in thicknesses within the same sheet of material, this is also true of the thickness tolerance between multiple sheets of material. The thickness tolerance of extruded acrylic sheets is +/- 5% while the thickness tolerance of cast acrylic sheets can be as high as +/- 15%.

- Optical clarity

While not quite as high as the optical clarity of clear cast acrylic sheet, clear extruded sheet still performs very well in this area. The economic cost of extruded acrylic is often required for high-volume projects, so unless the highest possible levels of optical clarity are required, then extruded an acrylic is an attractive option.

- Weather resistant

With excellent resistance to the elements, a clear extruded acrylic sheet performs very well outside. No significant changes in appearance are expected over 10 years.

- Fabrication

Anti-glare acrylic sheet is very easy to work with.

- Vacuum forming

Extruded acrylic is suitable for vacuum forming making it a popular choice when complex shapes are required.

Production process

Clear extruded acrylic sheets and clear cast acrylic sheets are visually very similar but are two different materials each with advantages and disadvantages and each produced by very different manufacturing processes. Extruded clear acrylic sheet is produced by an extrusion process, acrylic resin pellets are heated to a molten mass which is continuously pushed through a die, the position of which determines the thickness of the sheet produced. Once through the die, the molten mass loses temperature and can be trimmed and cut to the required sheet sizes. The continuous nature of the extruded acrylic production process produces larger batches than that of cast acrylic production making it a more economical material. If you are looking for anti-glare acrylic sheets, please feel free to contact us.