Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

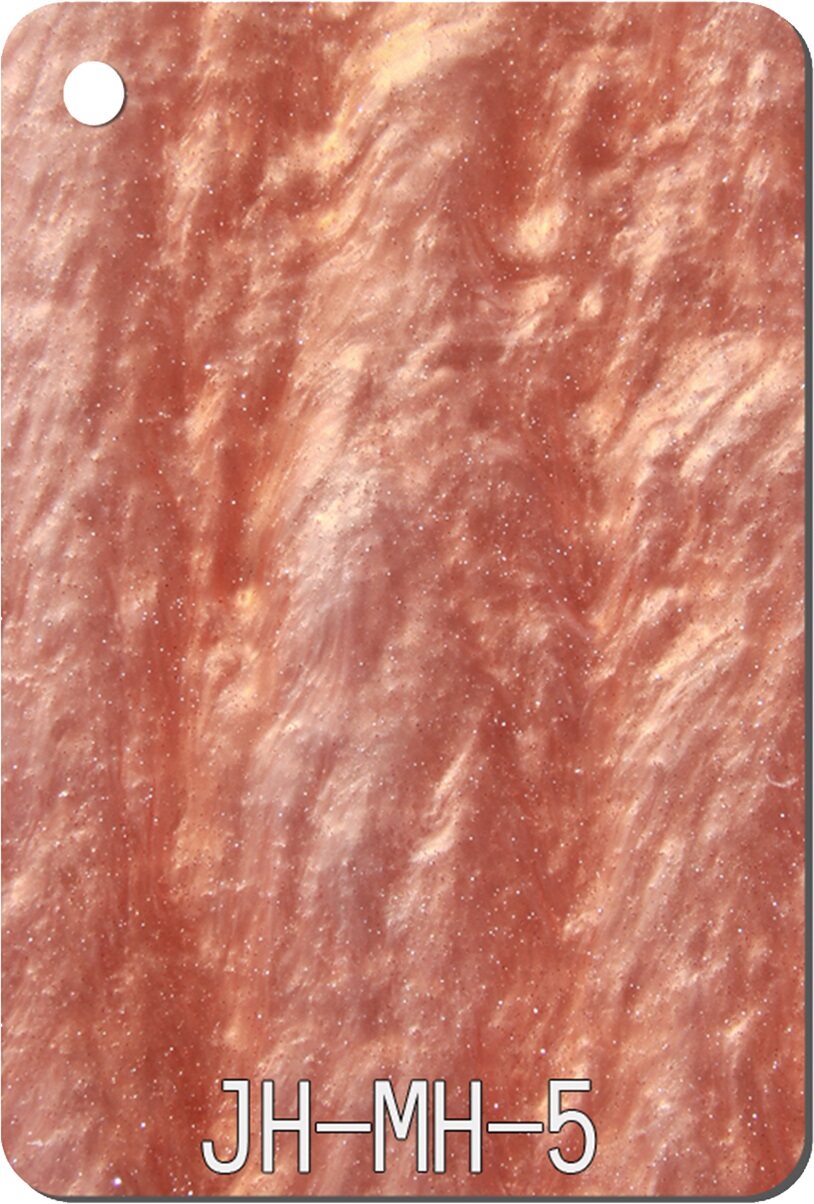

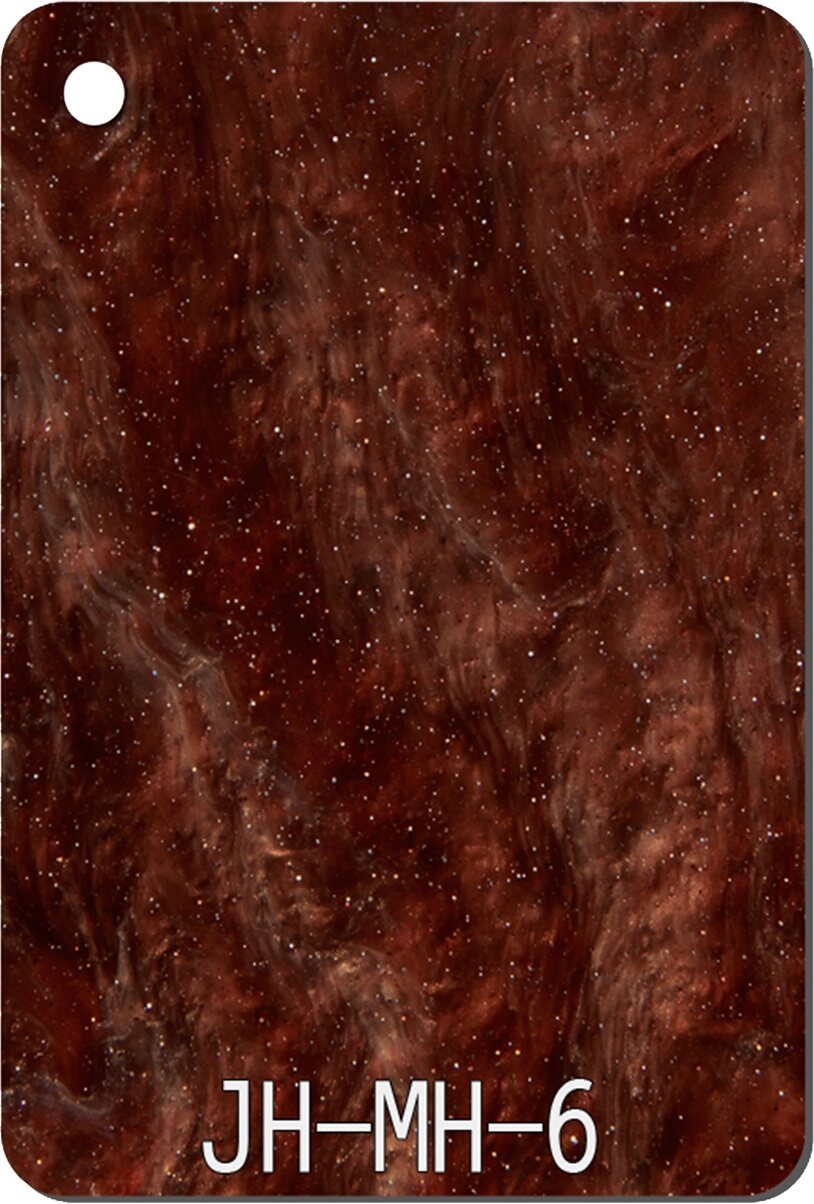

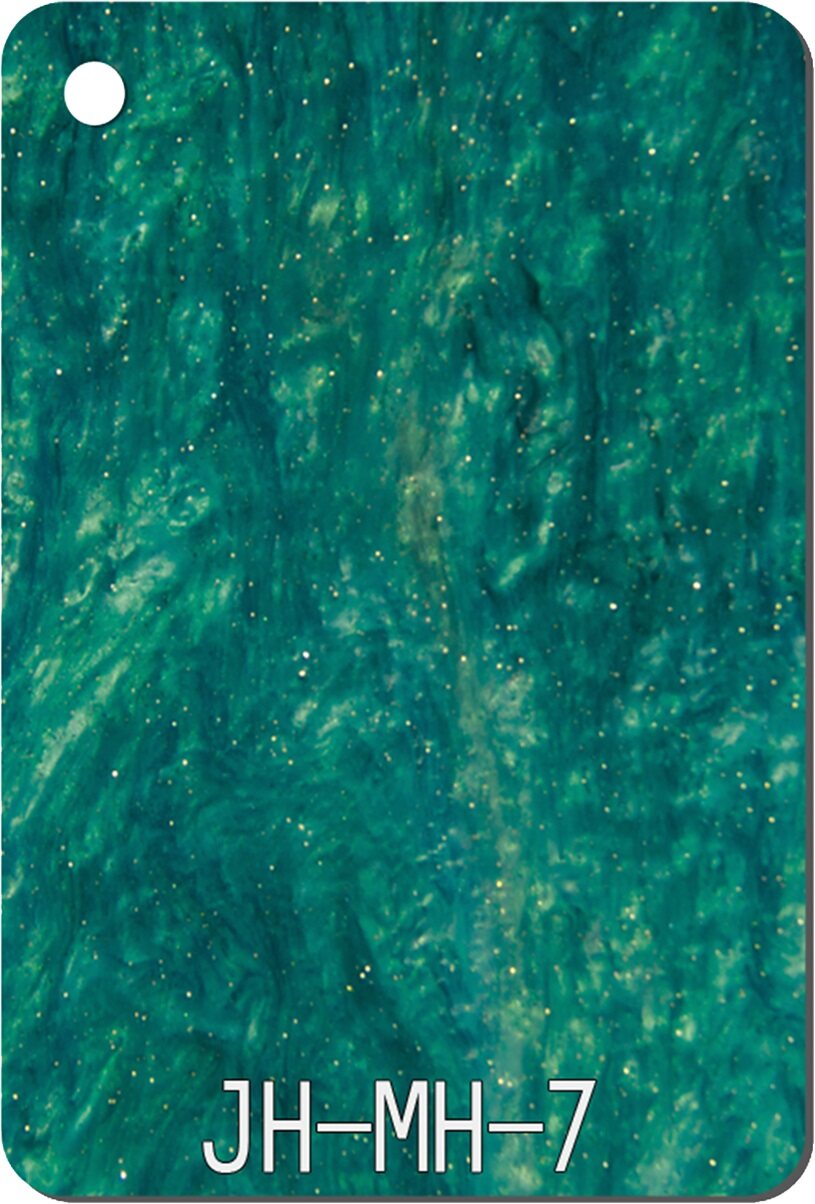

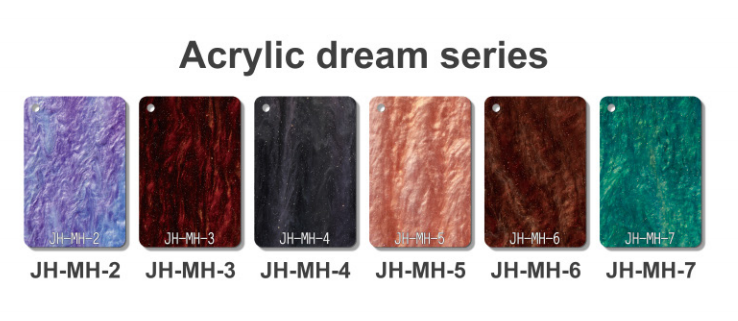

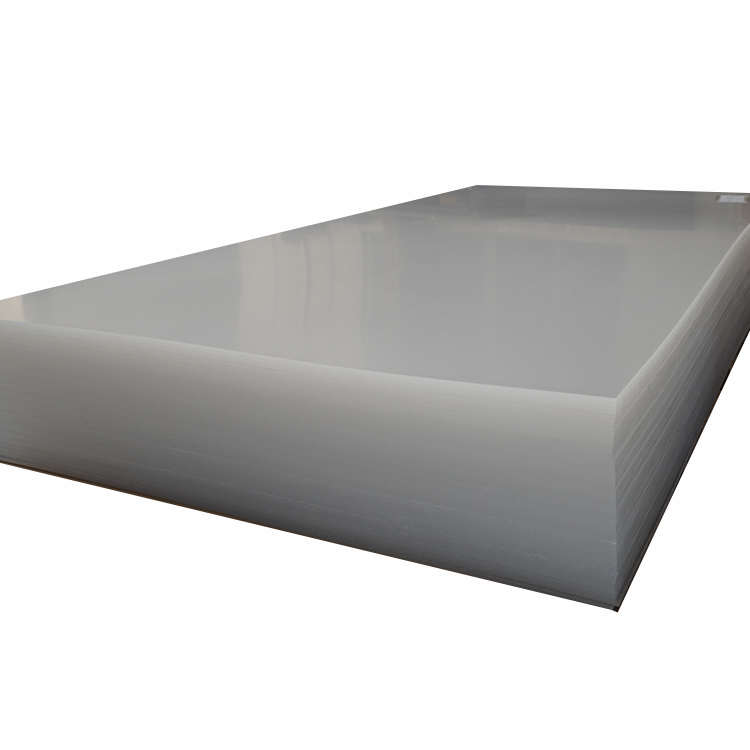

Decorative Dream Pattern Acrylic Sheets

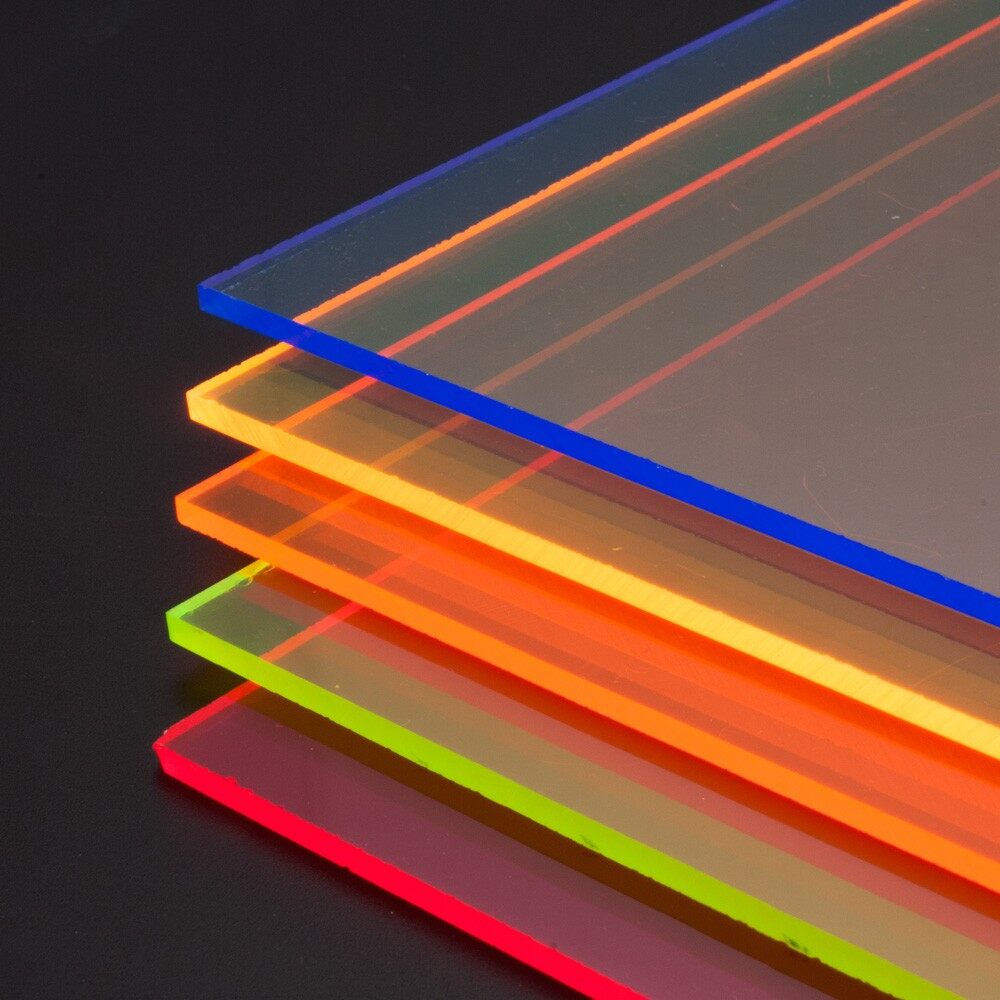

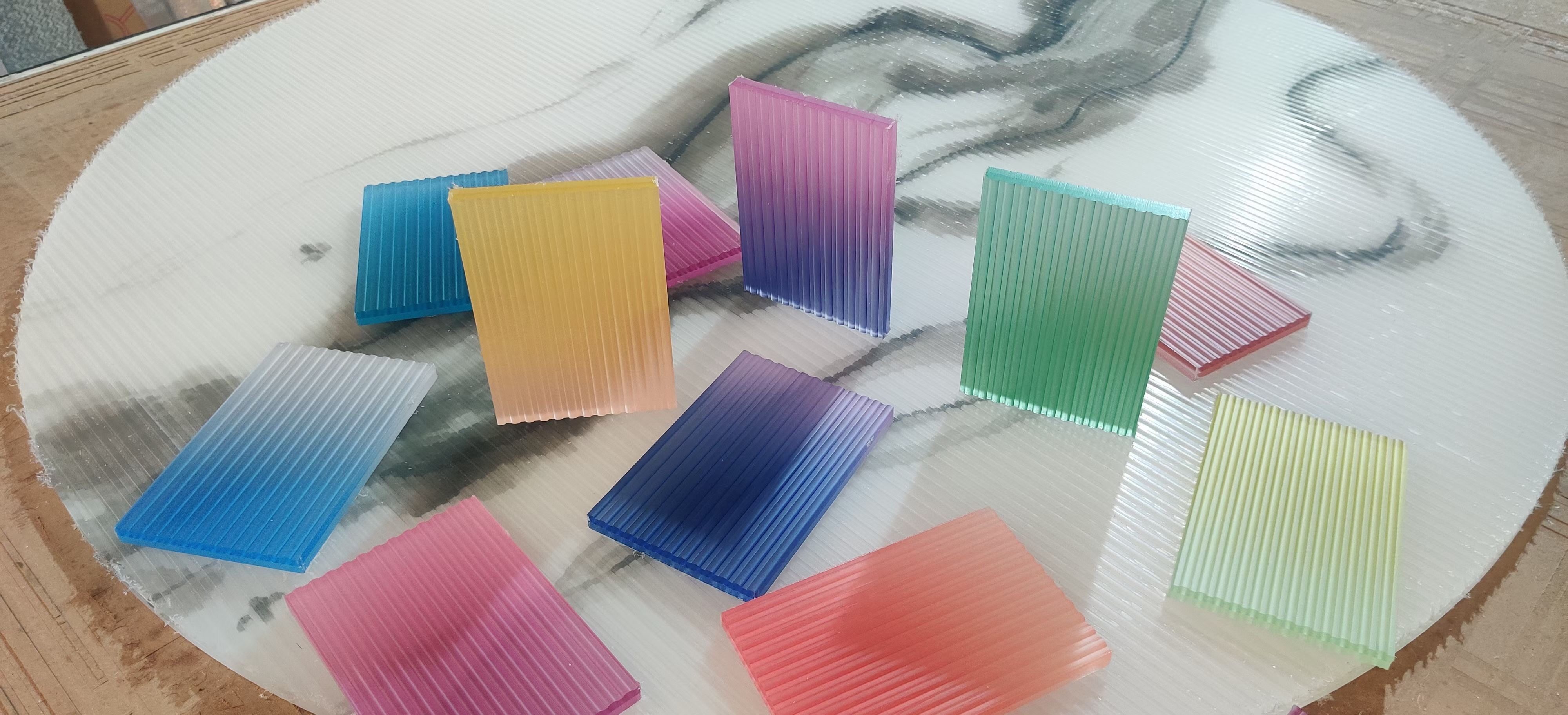

Dream pattern acrylic sheets are renowned for their exceptional clarity and transparency, offering a modern aesthetic to any project. These sheets boast superior chemical stability and weather resistance, ensuring longevity and durability in various environments. The ease of dyeing and straightforward manufacturing process make them a versatile choice for both commercial and construction applications. Available in an array of colors, patterns, and sizes, the sheets can be customized to fit specific design needs, including a selection of styles and the option to incorporate logos.

Our dream pattern acrylic sheets come with a protective laser-safe film to guard against damage during handling and laser cutting. While the film application is generally precise, minor imperfections like small bubbles may occur, but these do not compromise the sheet’s quality. For best results, remove the protective film before laser cutting to prevent heat damage to the film. Exercise caution when peeling off the film to keep the acrylic surface in perfect condition. Handle the masking process gently to avoid scratches. Our acrylic sheets are crafted to high-quality standards, ensuring a superior finish for your projects.

Features of Dream Pattern Acrylic Sheet

Visual Impact: The decorative dream pattern acrylic sheet boasts a mesmerizing design that can elevate the aesthetic of any space, serving as a focal point or a subtle decorative element.

Versatility: Dream Pattern Acrylic Sheets are adaptable to various applications, from wall accents to furniture inlays, making them a go-to choice for designers looking for versatile decorative plastic panels.

Durability: Crafted to last, these decorative acrylic sheets maintain their dream pattern and resist wear, ensuring long-term appeal and functionality.

Workability: The ease of customization and installation makes Dream Pattern Acrylic Sheets a favorite among those who work with decorative plastic panels, allowing for creative freedom in design projects.

Light Diffusion: The unique pattern on these decorative acrylic sheets creates a soft lighting effect, perfect for spaces that require ambient illumination with a decorative touch.

Specification of Dream Pattern Acrylic Sheet

|

Product Name |

Dream Pattern Acrylic Sheet |

|

Material |

Acrylic/PMMA |

|

Production Type |

Cast |

|

Tolerance |

+/-0.1mm in thickness, +/-1.0mm in length and width |

|

Surface Finish |

Both Sides are Glossy |

|

Protection |

Masking on Both Sides with PE Films |

|

Cutting Techniques |

Laser, CNC Router, Table Saw, Scroll Saw, Jeweler's Saw |

Maintenance Method of Dream Pattern Acrylic Sheet

- Heat Sensitivity: Avoid exposing the sheets to temperatures above 70 degrees Celsius to prevent deformation.

- Scratch Repair: For light scratches, polish gently with toothpaste and a soft cloth. Do not use sandpaper as it can damage the dream pattern.

- Cleaning: Use a soft cloth for cleaning and avoid abrasive or granular cleaners to protect the sheet’s clarity.

- Careful Handling: Protect the sheets from cracks and damage by handling them with care, especially during transport and installation.

- Thermal Expansion: Consider the acrylic’s thermal expansion during installation to prevent warping.

- Repair: If damaged, repair with IPS adhesive or methylene chloride-based adhesives to maintain the integrity of the dream pattern.

- Polishing: Maintain the shine with liquid polishing wax and a soft cloth to enhance the decorative pattern.