Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

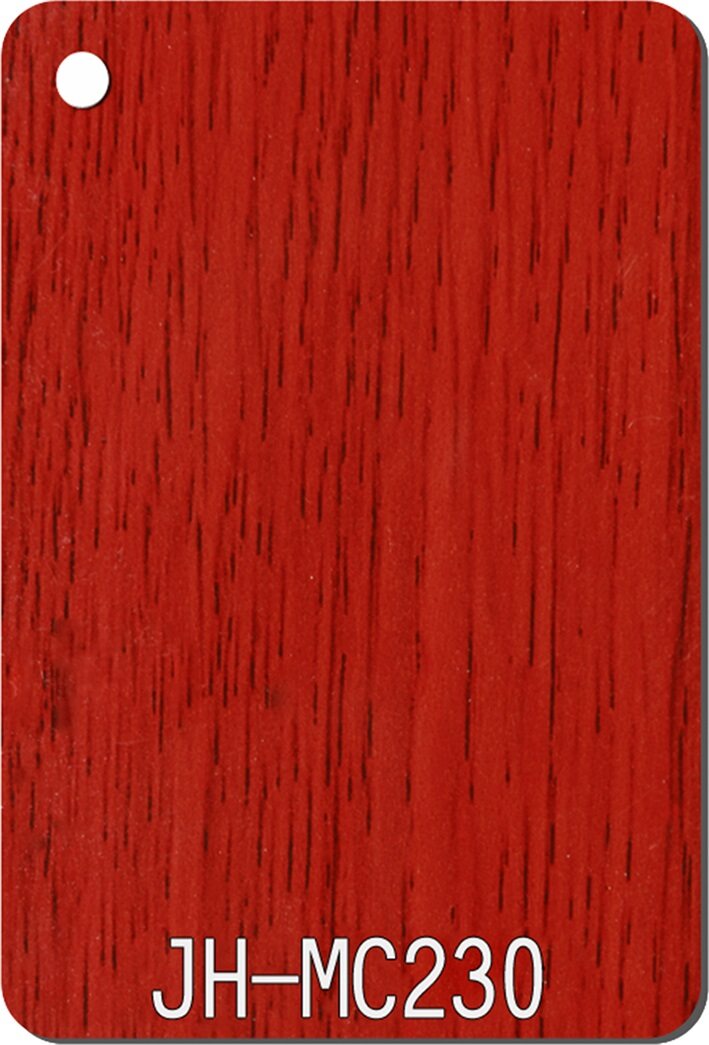

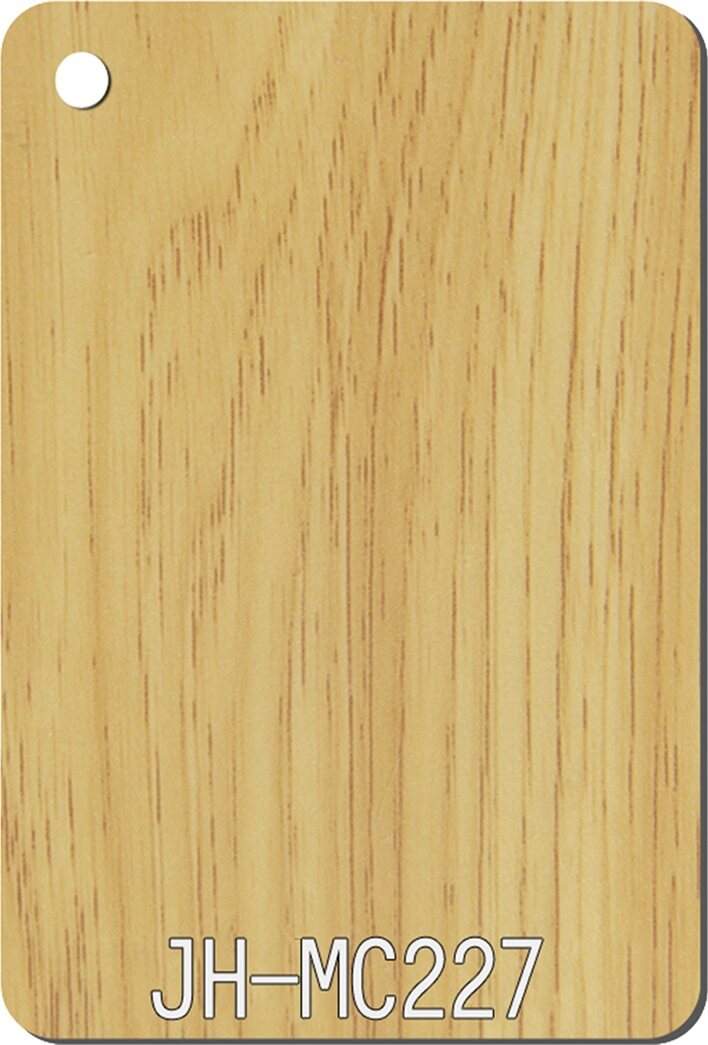

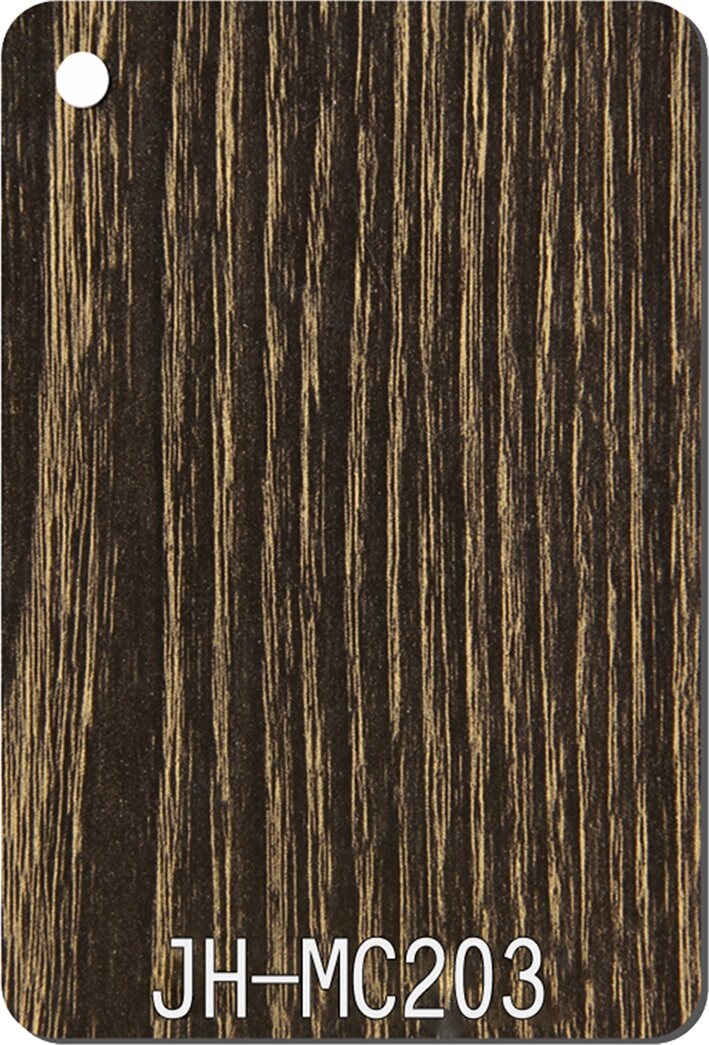

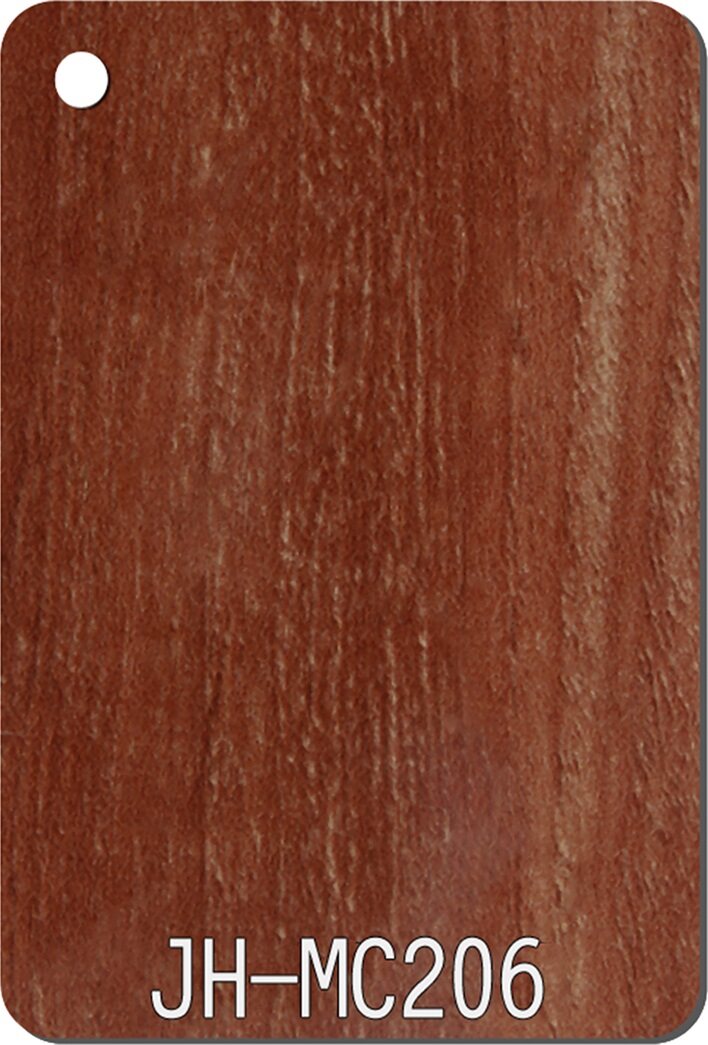

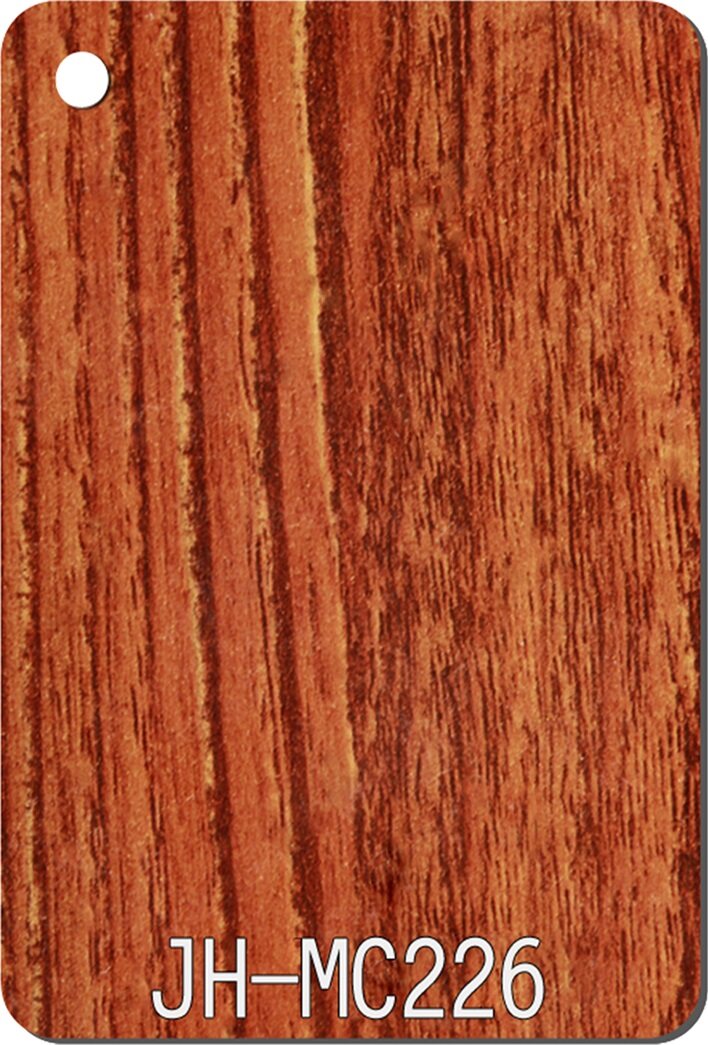

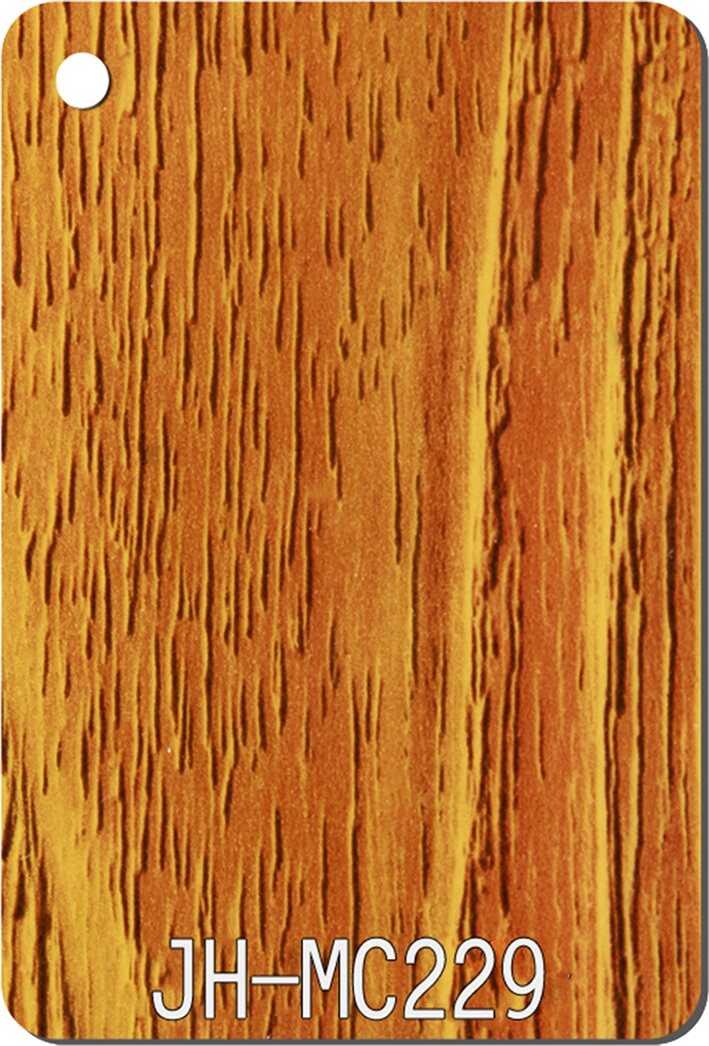

Wood Grain Acrylic Sheet

Experience the seamless integration of nature’s charm and contemporary resilience with our wood grain acrylic sheets. These sheets deliver the timeless, inviting look of wood paired with the superior qualities of acrylic, establishing them as a prime selection for diverse design and architectural endeavors.

Our wood grain acrylic sheets are crafted to emulate the detailed textures and deep hues of authentic wood while offering the robustness, adaptability, and low maintenance that acrylic is known for. Ideal for crafting eye-catching visual elements, these sheets are a perfect fit for enhancing both residential and commercial environments without the limitations associated with real wood.

The wood grain acrylic sheet marries the visual allure of timber with the hard-wearing and enduring nature of acrylic. This cutting-edge material is apt for an array of uses, from crafting elegant furniture to installing stylish wall paneling and ornamental accents. It presents a wood-like appearance so authentic it’s almost indistinguishable from actual lumber, earning it favor among designers and architects.

Features of Wood Grain Acrylic Sheet

- Authentic wood grain patterns and colors

- High resistance to impact and shattering

- UV stabilized to prevent fading and maintain color vibrancy

- Lightweight and easy to handle compared to real wood

- Resistant to moisture, making it ideal for use in humid or damp environments

- Easy to cut, drill, and shape for custom applications

- Simple to clean and requires minimal maintenance

Advantages of Wood Grain Acrylic Sheet

1. Versatility: Our Wood Grain Acrylic Sheets can be used in a multitude of settings, from home decor to commercial design, offering the flexibility to meet any project’s requirements.

2. Cost-Effective: Enjoy the luxurious look of wood at a fraction of the cost, with the added benefit of lower maintenance expenses over time.

3. Eco-Friendly: For those seeking a sustainable option, our acrylic sheets provide an eco-friendly alternative to traditional wood, reducing the demand for timber and helping to preserve forests.

4. Longevity: Unlike natural wood, our Wood Grain Acrylic Sheets will not warp, rot, or deteriorate over time, ensuring a long-lasting and attractive finish.

5. Ease of Installation: The lightweight nature of acrylic makes these sheets easy to transport and install, saving time and labor costs on any project.